![]()

With the Five Immutable Principles in hand, let’s start with What Does Done Look Like? To answer this question, we need units of measure to define what this means.

This first principle, when missing, is a primary root cause of project failure. Projects many times start with the notion of requirements gathering, without the understanding of how each requirement is traceable to the capabilities needed to accomplish the project mission.

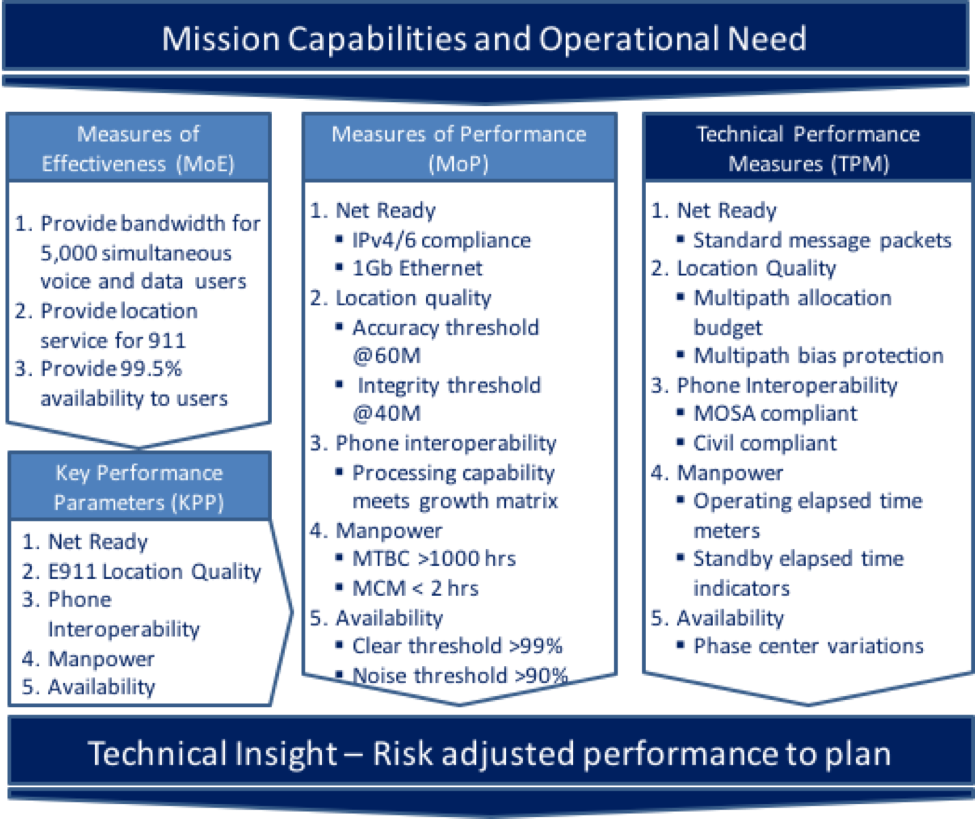

Stating with what Done looks like in units of measure meaningful to the decision makers, lays the foundation for project success. [1] These units of measure start with Effectiveness and Performance of the project outcome and their ability to accomplish the mission, fulfill the business goal, or solve a problem. As well, Technical Performance Measures (TPM) and Key Performance Parameters (KPP) are used to further define what Done looks like.

The document containing these four measures is a Concept of Operations (ConOps), a Statement of Objectives (SOO), or a business or technical strategy document. The ConOps documents the characteristics of a proposed system from the viewpoint of those using the system. It communicates the quantitative and qualitative system characteristics to all stakeholders, including those who will develop the projects deliverables.

These measures are defined as:

- Measures of Effectiveness ‒ are operational measures of success closely related to the achievements of the mission or operational objectives evaluated in the operational environment, under a specific set of conditions. MoE’s are stated in units meaningful to the buyer, and focus on capabilities independent of any technical implementation, and are connected to mission success. MoE’s belong to the End User.

- Measures of Performance ‒ characterize physical or functional attributes relating to the system operation, measured or estimated under specific conditions. MoP’s assure the system has the capability and capacity to perform, and are used to assure the system meets the design requirements to satisfy the MoE. MoP’s belong to the project. They are developed by Systems Engineers and analyzed by project management and project controls.

- Key Performance Parameters ‒ represent the capabilities and characteristics so significant, that failure to meet them can be cause for reevaluation, reassessment, or termination of the program. KPP’s have a threshold or objective value, characterize the major drivers of performance, and are consider Critical to Customer (CTC). The acquirer defines the KPP’s during the operational concept development phase of the project.

- Technical Performance Measures ‒ determine how well a system is satisfying or expected to satisfy a technical requirement or goal. TPMs assess design progress, define compliance to performance requirements, identify technical risk, are limited to critical thresholds, and include projected performance.

These measures are connected in an example of a public safety surveillance system.

Without these measures defined, validated, and confirmed to be feasible, we’re lowering the Probability of Project Success (PoPS) before we even start.

Next week, let’s build the Integrated Master Plan and Integrated Master Schedule to implement the deliverables to fulfill the Capabilities, MOE’s, MOP’s, and TPM’s and KPP’s.

[1] “Technical Measurement,” INCOSE-TP-2003-020-01

Glen Allenman is part of the GovLoop Featured Blogger program, where we feature blog posts by government voices from all across the country (and world!). To see more Featured Blogger posts, click here.

Leave a Reply

You must be logged in to post a comment.